ISO-9001-Lead-Auditor Exam Dumps - QMS ISO 9001:2015 Lead Auditor Exam

Searching for workable clues to ace the PECB ISO-9001-Lead-Auditor Exam? You’re on the right place! ExamCert has realistic, trusted and authentic exam prep tools to help you achieve your desired credential. ExamCert’s ISO-9001-Lead-Auditor PDF Study Guide, Testing Engine and Exam Dumps follow a reliable exam preparation strategy, providing you the most relevant and updated study material that is crafted in an easy to learn format of questions and answers. ExamCert’s study tools aim at simplifying all complex and confusing concepts of the exam and introduce you to the real exam scenario and practice it with the help of its testing engine and real exam dumps

'XYZ' has already sent to you a list with all documented procedures and work instructions related to the services provided to 'ABC' (a quality manual is not included in the list).

To complete the audit planning which additional information would you ask to XYZ to submit? Select four.

Select the term that best describes the purpose of retaining documented information in a quality management system to ISO 9001.

Which two of the following work documents are not required for audit planning by an auditor conducting a certification audit?

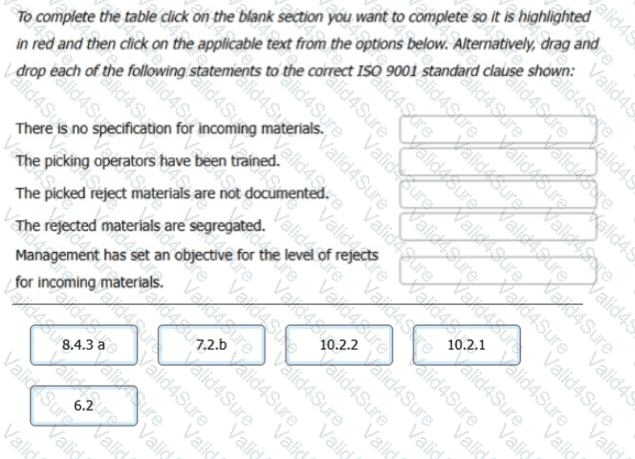

You are conducting an ISO 9001 audit of a Materials Recycling Facility (MRF). The company

processes waste plastics into raw material for plastic bottle manufacturers. You reach the manual

picking line where operators are removing contaminant materials from incoming products, such as

plastic bags, plastic film and badly contaminated items that would compromise the recycling process.

You interview the line supervisor.

You: "Why are these plastic items being rejected at this stage?"

Auditee: "They do not meet our processing standards."

You: "What is the reason for that?"

Auditee: "These items are likely to damage the machinery down the line. They can also

compromise our quality standards. We need to protect our reputation for good quality output

materials."

You: "What happens to the rejected items?"

Auditee: "Some get melted down in another process later on and some are disposed of as waste

products that cannot be recycled."

You: "What happens to the waste products?"

Auditee: "I'm not sure. I suppose they go to landfill."

After further auditing, you have gathered additional evidence.

An audit team of three people is conducting a Stage 2 audit to ISO 9001 of an engineering organisation that manufactures sacrificial anodes for the oil and gas industry in marine environments. These are aluminium products designed to prevent corrosion of submerged steel structures. You, as one of the auditors, find that the organisation has shipped anodes for Project DK in the Gulf of Mexico before the galvanic efficiency test results for the anodes have been fully analysed and reported as required by the customer. The Quality Manager explains that the Managing Director authorised the release of the anodes to avoid late delivery as penalties would be Imposed. The customer was not informed since the tests very rarely fall below the required efficiency. You raise a nonconformity against clause 8.6 of ISO 9001.

At the Closing meeting, the audit team leader presents the findings of the audit and comes to the above

nonconformity. The Quality Manager produces the test report for Project DK, which shows an acceptable galvanic efficiency, and presents an email from the customer confirming acceptance of the anodes. He asks that the nonconformity be withdrawn.

Which two of the following responses by the audit team leader would be acceptable?

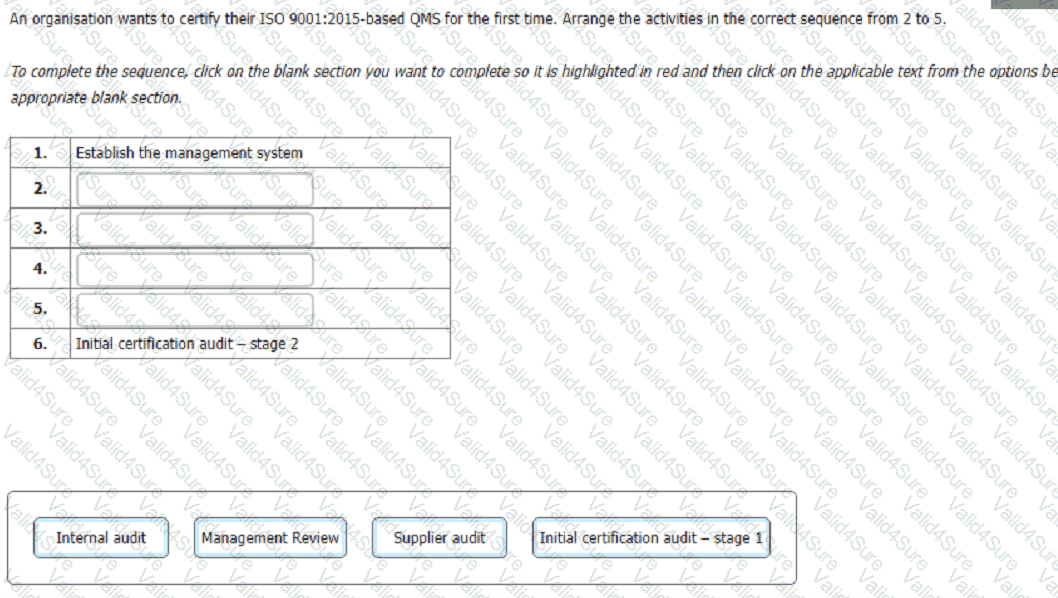

An organisation wants to certify their ISO 9001:2015-based QMS for the first time. Arrange the activities in the correct sequence from 2 to 5.

To complete the sequence, click on the blank section you want to complete so it is highlighted in red and then click on the applicable text from the options below. Alternatively, drag and drop the

options to the appropriate blank section.

Scenario 5: Mechanical-Electro (ME) Audit Stages

Mechanical-Electro, better known as ME, is an American company that provides mechanical and electrical services in China. Their services range from air-conditioning systems, ventilation systems, plumbing, to installation of electrical equipment in automobile plants, electronic manufacturing facilities, and food processing plants.

Due to the fierce competition from local Chinese companies and failing to meet customer requirements, ME's revenue dropped significantly. In addition, customers' trust and confidence in the company decreased, and the reputation of the company was damaged.

In light of these developments, the top management of ME decided to implement a quality management system (QMS) based on ISO 9001. After having an effective QMS in place for over a year, they applied for a certification audit.

A team of four auditors was appointed for the audit, including Li Na as the audit team leader. Initially, the audit team conducted a general review of ME's documents, including the quality policy, operational procedures, inventory lists, QMS scope, process documentation, training records, and previous audit reports.

Li Na stated that this would allow the team to maintain a systematic and structured approach to gathering documents for all audit stages. While reviewing the documented information, the team observed some minor issues but did not identify any major nonconformities. Therefore, Li Na claimed that it was not necessary to prepare a report or conduct a meeting with ME's representatives at that stage of the audit. She stated that all areas of concern would be discussed in the next phase of the audit.

Following the on-site activities and the opening meeting with ME's top management, the audit team structured an audit test plan to verify whether ME’s QMS conformed to Clause 8.2.1 (Customer Communication) of ISO 9001.

To do so, they gathered information through group interviews and sampling. Li Na conducted interviews with departmental managers in the first group and then with top management. In addition, she chose a sampling method that sufficiently represented customer complaints from both areas of ME's operations.

The team members were responsible for the sampling procedure. They selected a sample size of 4 out of 45 customer complaints received weekly for electrical services and 2 out of 10 complaints for mechanical services.

Afterward, the audit team evaluated the evidence against the audit criteria and generated the audit findings.

According to scenario 5, Li Na conducted group interviews with departmental managers and top management by herself. Is this in accordance with audit best practices?